① Solid state batteries are facing intensive catalysis. In terms of A-shares, the cumulative maximum increase in Sanxiang New Materials’s share price in the past month was 73.52%;

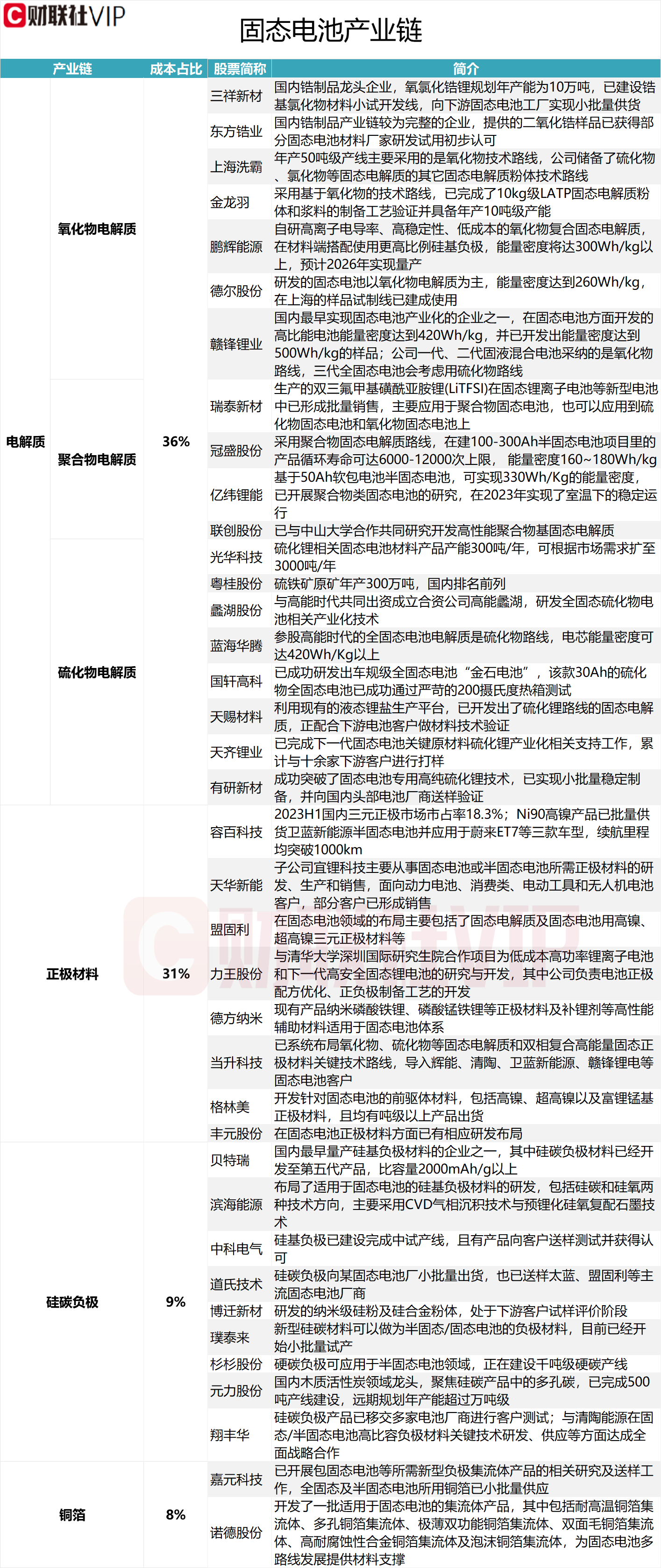

② Combing the list of listed companies in the solid-state battery industry chain with cost ratios exceeding 30% and specific business conditions (attached table).

Cailian News, March 8 (Editor Li Chen)In March, solid-state batteries welcomed intensive catalysis, including the all-solid-state battery technology exchange conference in early March. Hyundai Motor also previously announced that it would release the “Dream” all-solid-state battery pilot production line in March. In addition, the news of the domestic and foreign solid-state battery industry chain is also constantly positive. Changan, Dongfeng Lantu, BYD and other car companies have successively disclosed the timetable for launching or mass production of solid-state batteries. agency saidThe loading pace of all-solid-state batteries is expected to gradually converge, that is, small batches/demonstration vehicles will be launched in 2027 and mass production in 2030.。

The concept of solid state batteries continues to take the lead,Sanxiang New Materials, which is committed to the research and development and production of solid-state battery electrolyte materials and key raw materials, has seen the largest share price increase in the past month by 73.52%Shanghai Ziba, which is steadily advancing in new solid-state electrolyte materials and other aspects, has seen a cumulative maximum increase in its share price of 65% in the past month. It plans to establish a joint venture with the main business of manufacturing, sales and export of solid-state power batteries and semi-solid energy storage batteries. The cumulative maximum increase in its share price in the past month is 53%.

Dongguan Securities Huang Xiuyu said in a research report released on February 28 that solid-state batteries have high-performance advantages and downstream demand continues to catalyze. With its two significant advantages of high energy density and high safety, solid-state batteries have become the next generation of high-performance lithium batteries. The industrialization process of solid-state batteries is accelerating, and the dawn of all-solid-state batteries is beginning to emerge. As the mass production schedule of all-solid-state batteries of head battery manufacturers has become clear, the start mass production time of all-solid-state batteries has been advanced to 2027, and the industrialization process of solid-state batteries is accelerating.The global solid-state battery market is expected to usher in rapid growth in the next few yearsAccording to EVTank, it is expected that by 2030, solid-state battery shipments are expected to exceed 600GWh, with a penetration rate of around 10% in the overall lithium battery, and the market size will exceed 250 billion yuan.

According to a previous review in the VIP Pandian Bao·Data column of the Financial Union, in the solid state battery industry chain,The area with a cost ratio of 36% is electrolytes。Among them, the A-share listed companies involved in the field of oxide electrolytes include Sanxiang Xincai, Dongfang Zirconium, Shanghai Xiba, Jinlongyu, Penghui Energy, Del and Ganfeng Lithium; the companies involved in the field of polymer electrolytes include Ruitai Xincai, Guansheng, Yiwei Lithium Energy and Lianchuang; the A-share listed companies involved in the field of sulfide electrolytes include Guanghua Technology, Yuegui, Lihu, Lanhai Huateng, Guoxuan High-tech, Tianci Materials, Tianqi Lithium and Youyan Xincai.

In addition, in the solid state battery industry chain,The area with a cost ratio of 31% is cathode materials, the A-share listed companies involved include Rongbai Technology, Tianhua Xinneng, Mengguli, Liwang, Defang Nano, Dangsheng Technology, Geminmei and Fengyuan; the area with a cost ratio of 9% is silicon carbon negative electrodes, and the companies involved include Baitri, Binhai Energy, Zhongke Electric, Dow Technology, Boqian Xincai, Shanshan, Yuanli and Xiangfenghua; the area with a cost ratio of 8% is copper foil, and the A-share listed companies involved include Jiayuan Technology and Nord. See the following figure for details:

Specifically,Sanxiang Xincai is a leading domestic enterprise in zirconium productsData shows that Sanxiang New Material Lithium Zirconium Oxychloride has a planned annual production capacity of 100,000 tons. A pilot development line for zirconium-based chloride materials has been built to supply small batches to downstream solid-state battery factories. Zhang Yuxuan and others from Northeast Securities stated in a research report released on December 27, 2024 that Sanxiang New Material Oxide Electrolyte has completed sample delivery for downstream customers to assemble into solid-state batteries for relevant performance testing. The pilot line design has been completed, and corresponding equipment supporting work is underway. Dongfang Zirconium said on Interactive Easy on December 9, 2024 thatAs the core of solid state batteries, there are three mainstream technical paths for solid state electrolytes: Polymers, oxides and sulfides. If oxide solid electrolytes such as lithium lanthanum zirconium oxide (LLZO) and lithium lanthanum zirconium titanium oxide (LLZTO) are used, there is a certain demand for zirconium dioxide. At present, the samples provided by the company have been initially recognized by some solid-state battery material manufacturers for R & D trials, and detailed sample experiments will be carried out in the future.

Data shows thatShanghai Shiba’s 50-ton annual production line mainly adopts the oxide technology route, the company has reserved other solid electrolyte powder technical routes for solid electrolytes such as sulfides and chlorides. The company’s solid-state batteries and their key material-related technologies are still in the research and development stage. Jin Longyu said on Interactive Easy on May 9, 2024 thatThe company’s semi-solid-state batteries have completed internal testing projects and have met safety standards., passed the test by the Shenzhen Institute of Metrology and Quality Inspection, its safety performance met the national standard requirements, and passed the 3mm acupuncture test. Penghui Energy stated on Interactive on September 4, 2024 that the solid-state battery released by the company this time replaces the separator and electrolyte by using a self-developed oxide composite solid electrolyte with high ionic conductivity, high stability and low cost., realizing solid-state battery process innovation and material innovation, and building a solid foundation for the company’s solid-state battery industrialization in terms of process and cost reduction.

Ganfeng Lithium Industry said on Interactive Exchange on March 3 thatThe company has completed the delivery of some solid-state battery samples and conducted testing and verification with multiple potential customers.。The company currently takes the oxide battery route as its main research and development direction, and actively explores the integration and innovation of multiple technical routes. The company has applied for a number of solid-state battery-related patents, covering core technologies such as electrolyte materials, electrode interface optimization, and battery manufacturing processes. Ganfeng Lithium Industry stated on Interactive on December 13, 2024 that the high-specific energy battery developed by the company in solid-state batteries has an energy density of 420Wh/kg, a cycle life of more than 700 times, and an energy density of 500Wh/kg has been developed. Samples can pass rigorous safety tests such as 200 ° C hot boxes and needle punching. Del shares said on Interactive Exchange on February 28 thatThe company’s solid-state battery products are mainly oxide electrolytes, which are characterized by high safety and high temperature resistance, adopts mature coating process, simple manufacturing process, advantages in performance and cost.

Lianchuang Co., Ltd. said on Interactive Exchange on February 24 thatThe company cooperates with Sun Yat-sen University to jointly research and develop high-performance polymer-based solid electrolyte materialsDuring the initial research and development process, three patent authorizations on solid electrolytes were obtained, including “a cross-linked polymer benchmark solid electrolyte containing double plasticizers combined with soft and hard segments and its preparation method and application.” Data shows that Guansheng adopts a polymer solid electrolyte route. The cycle life of the products in the 100-300Ah semi-solid battery project under construction can reach the upper limit of 6,000 – 12,000 cycles, and the energy density is 160 – 180Wh/kg. Ruitai Xincai stated on Interactive Exchange on November 18, 2024 thatThe company’s product lithium bis (trifluoromethylsulfonimide) is mainly used in polymer solid-state batteries as a solid-state battery electrolyte material, can also be applied to sulfide solid-state batteries and oxide solid-state batteries. Yiwei Lithium Energy stated on Interactive on May 29, 2024 that based on the 50Ah soft-pack battery semi-solid battery, an energy density of 330Wh/Kg can be achieved and a cycle life of more than 2000 times. In the field of solid-state batteries, the company has carried out research on polymer solid-state batteries, and has initially achieved stable operation at room temperature and will be used in miniature electronic products.

Blue Sea Huateng said on Interactive Easy on February 18 thatThe research and development of sulfide all-solid-state lithium batteries invested by the company in the high-energy era is progressing smoothly, the construction of an automated production test line has been completed, and small batch production of batteries within 5Ah has been achieved. Currently, preparations are being made for the construction of a batch production line. Data shows thatGuanghua Technology’s lithium sulfide-related solid battery material product production capacity is 300 tons/year, which can be expanded to 3000 tons/year according to market demand; Lihu Co., Ltd. and High-Energy Times jointly funded the establishment of a joint venture company, High-Energy Lihu, to develop industrialization technologies related to all-solid-state sulfide batteries; Tianqi Lithium has completed the industrialization of the key raw material for the next generation of solid state batteries. Support work related to the industrialization of lithium sulfide has been carried out with more than ten downstream customers.

Youyan Xincai said on Interactive Easy on January 20 thatIn terms of solid-state battery materials, Xinyuanbang oxide electrolytes, a company participating in the company, have reached mass production stage, sulphides and polymer electrolytes are in the supply stage of small batches. Guoxuan High-tech said on Interactive Easy on January 6 that the company is fully committed to developing sulfide all-solid-state batteries, and is also planning the development of halide all-solid-state batteries. The company has successfully developed a vehicle-sized sulfide all-solid-state battery “Jinshi Battery” and passed the rigorous 200-degree Celsius hot-box test, providing a new realization path for high specific energy and high safety battery systems. Yuegui Shares stated on Interactive Exchange on November 4, 2024 thatThe company’s annual output of pyrite raw ore is 3 million tons, ranking among the top in China。Tianci Materials stated on Interactive Easy on April 22, 2024 that the company’s semi-solid electrolytes and all-solid electrolytes of oxides and sulfides are in the small to pilot stages.